Coffee Processing

Irrespective

of the harvesting method, green coffee beans and overripe

coffee cherries inevitably end up mixed with the perfectly

ripe cherries and must be separated during coffee processing.

Overripe coffee cherries, undeveloped coffee cherries,

sticks and leaves float in water.

Ripe coffee beans and green coffee cherries are dense

and sink. Therefore,

the first step in coffee production consists of separating the

"floaters" from the "sinkers."

The coffee floaters are usually sent directly to the patio

to be dried and are often slated for internal consumption.

The ripe and green cherries can be sent to the patios

to be dried using the natural process of preparing coffee or can be sent

to the coffee pulping machines.

Irrespective

of the harvesting method, green coffee beans and overripe

coffee cherries inevitably end up mixed with the perfectly

ripe cherries and must be separated during coffee processing.

Overripe coffee cherries, undeveloped coffee cherries,

sticks and leaves float in water.

Ripe coffee beans and green coffee cherries are dense

and sink. Therefore,

the first step in coffee production consists of separating the

"floaters" from the "sinkers."

The coffee floaters are usually sent directly to the patio

to be dried and are often slated for internal consumption.

The ripe and green cherries can be sent to the patios

to be dried using the natural process of preparing coffee or can be sent

to the coffee pulping machines.

Coffee Processing Equipment

The first stage of coffee pulping

is used to remove the green coffee cherries from the ripe cherries.

In the coffee pulping machinery, the internal pressure is monitored

to push the coffee against a screen with holes only large

enough for a coffee bean (not cherry) to pass through.

Since the ripe cherries are soft, they break and the coffee

seed is released through the screen.

For more information about coffee processing equipment, view this video

showing coffee pulping machines: medium (5.6 Mb) or small (1.5

Mb).

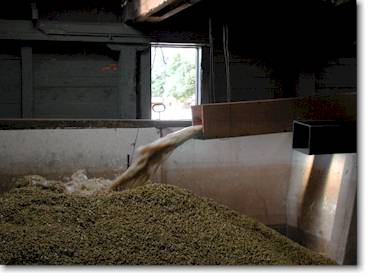

Pulping Coffee

The green cherries are

hard and cannot be pulped.

Instead of passing through the screen, the green

coffee beans pass to the end of the barrel system and are separated

from the ripe coffee beans.

The pressure inside the barrel controls how many

cherries will be pulped. A very high pressure will cause all of the cherries including

the green beans to be pulped.

It is necessary to continuously monitor the pressure

so that about 3% of ripe cherries are not pulped and are

removed with the green cherries.

This margin of error ensures that no green cherries

are mistakenly pulped.

The pulp and coffee beans are then separated by centrifugal

force and a barrel screen system.

For more information about coffee pulping, view this video showing the

inside of the pulp separator: medium (1.24 Mb). Video showing another pulp separator in

action: medium (4.2 Mb) or small (985 Kb).

Coffee Fermentation

The coffee beans covered in the

slippery mucilage can be sent to the patios to dry as pulped

natural coffees or can be sent to coffee fermentation tanks.

The coffee fermentation tanks are used to remove the mucilage

before drying. The

pulped coffee beans are put into cement tanks with water and are

allowed to ferment for 16-36 hours. On

the way to the fermentation tanks, another density separation

can occur. The highest quality coffees are the densest and should be separated and fermented in a different

tank.

For more information about molecular density sorting, view this video showing a newly designed density sorting

tank: medium (6.5 Mb) or small (1.4 Mb).

The

coffee fermentation time depends on a number of factors including

the amount of coffee fermenting, water temperature, and

humidity. The mucilage

is made up of pectin materials including protopectin (33%),

reducing sugars including glucose and fructose (30%), non-reducing

sugars such as sucrose (20%), and cellulose and ash (17%)

(Wrigley,

455). Protopectin is not water soluble and will

hydrolyze to pectinic acid in the fermentation tanks (Wrigley,

455). Hydrolysis of the protopectin and degradation

of the pectin by enzymes is the process that occurs to remove

the mucilage during fermentation (Wrigley, 455). Currently,

the best way of determining the end of coffee fermentation is to

feel the coffee beans to determine if they are still encased

in mucilage. If

the coffee beans are fermented for 36-72 hours, stinker beans develop.

Lactic, acetic, and propionic acids are produced in this

process and are believed to prevent the traditional fermentation

taste by inhibiting mold growth that regularly occurs during

drying on a patio in humid conditions (Wrigley).

The

coffee fermentation time depends on a number of factors including

the amount of coffee fermenting, water temperature, and

humidity. The mucilage

is made up of pectin materials including protopectin (33%),

reducing sugars including glucose and fructose (30%), non-reducing

sugars such as sucrose (20%), and cellulose and ash (17%)

(Wrigley,

455). Protopectin is not water soluble and will

hydrolyze to pectinic acid in the fermentation tanks (Wrigley,

455). Hydrolysis of the protopectin and degradation

of the pectin by enzymes is the process that occurs to remove

the mucilage during fermentation (Wrigley, 455). Currently,

the best way of determining the end of coffee fermentation is to

feel the coffee beans to determine if they are still encased

in mucilage. If

the coffee beans are fermented for 36-72 hours, stinker beans develop.

Lactic, acetic, and propionic acids are produced in this

process and are believed to prevent the traditional fermentation

taste by inhibiting mold growth that regularly occurs during

drying on a patio in humid conditions (Wrigley).

For more information about coffee fermentation, view this video

showing the coffee in the coffee fermentation tanks: medium (1.1 Mb).

Coffee Drying

From

the coffee fermentation tanks, the beans are moved to drying patios

and dried to 11-12% moisture content. See coffee drying

section for more details.

A small portion of the lot is hulled and milled by a

mini-huller. Three

hundred grams of coffee is classified for defects (100 grams

is often used), and the percentage of each screen size is determined.

Then, 200-300 grams of coffee is roasted in a sample

roaster and cupped to determine coffee quality.

Ideally no lots will be mixed until the coffee has been

classified and cupped.

The coffee remains in pergamino until shipment time to

help protect the flavor and aroma of the coffee.

For a complete look at coffee production, view this video

showing the steps of coffee processing (shown individually above): Medium

(14.6 Mb) and Small

(4.9 Mb).

For more information about coffee processing, visit the National Coffee Association or Wikipedia.

Related

Articles

Flavor Characteristics Due to Processing

Harvesting

Coffee

Coffee

Drying

Density Sorting Coffee

Color Sorting Coffee

Coffee Storage